Technology behind Geek+ Solutions

Geek+ : The future of warehousing robotics

Geek+ robots are equipped with LiDAR, visual SLAM, 2D code system & inertial navigation system, enabling it for localisation, navigation, perception, and precision controls. These robots can reduce energy consumption by up to 75% compared to manual warehouses, work 24/7 in low light, batteries have a 1:16 charge-discharge ratio, longer service life, and better efficiency.

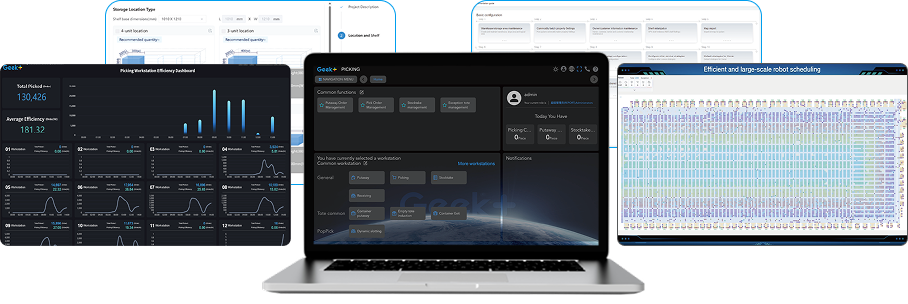

All-in-one software suite

The Geekplus Software Suite is a series of modular software products to support efficient, reliable and flexible robot-based smart warehouse solutions. The Geekplus Software Suite supports multiple languages and provides open interfaces, ensuring that customers and partners can easily use and integrate with.

P Series

Picking Robots

Geek+ multiple-model picking robots, with their maximum load of 1200kg and their ability to reduce 50-70% of manual labor and increase picking accuracy to 99.99%, is the preferred choice for businesses looking to reduce costs and raise efficiency using automated warehouse robots.

RS Series

Vertical Robots

Geek+ RS- Series robots can improve picking efficiency by 2 to 3 times on average and they are flexible in their implementation, allowing for the desired addition or removal of robots according to customer requirements; they require little to no modification to project site and boast a short ROI cycle.

X Series

4 way movement robots

X-Series Storage Robot revolutionizes warehouse operations with its four-way horizontal movement along the tracks within 3-dimensional racking systems, narrow-body design reducing aisle footprint by 40% , enabling fully automated high-density storage, precision retrieval and industrial-grade load capacity.

S Series

Sorting Robots

Geek+ sorting robots are highly efficient, automated and flexible, achieving nearly 10 times the efficiency of traditional sorting systems; their multi-sensor safety obstacle avoidance features also ensure the safety of on-site implementation.

F Series

Forklift Robots

Geek+ F-Series moving robots have a maximum carrying load of 2000kg, and are supported by laser SLAM, QR code navigation and other navigation methods to ensure smooth, accurate and safe robot operations.

P Series

Picking Robots

Geek+ multiple-model picking robots, with their maximum load of 1200kg and their ability to reduce 50-70% of manual labor and increase picking accuracy to 99.99%, is the preferred choice for businesses looking to reduce costs and raise efficiency using automated warehouse robots.

.png?width=335&height=184&name=35014f694a5caa8f1c66308f2da3a58117b67bb4%20(1).png)

RS Series

Vertical Robots

Geek+ RS- Series robots can improve picking efficiency by 2 to 3 times on average and they are flexible in their implementation, allowing for the desired addition or removal of robots according to customer requirements; they require little to no modification to project site and boast a short ROI cycle.

X Series

4 way movement robots

X-Series Storage Robot revolutionizes warehouse operations with its four-way horizontal movement along the tracks within 3-dimensional racking systems, narrow-body design reducing aisle footprint by 40% , enabling fully automated high-density storage, precision retrieval and industrial-grade load capacity.

S Series

Sorting Robots

Geek+ sorting robots are highly efficient, automated and flexible, achieving nearly 10 times the efficiency of traditional sorting systems; their multi-sensor safety obstacle avoidance features also ensure the safety of on-site implementation.

F Series

Forklift Robots

Geek+ F-Series moving robots have a maximum carrying load of 2000kg, and are supported by laser SLAM, QR code navigation and other navigation methods to ensure smooth, accurate and safe robot operations.

Safety Solutions

The Geek+ system safety solution creates a secure operational environment for all scenarios, providing protection & effective safety measures for personnel. It meets regularity standards for electrical safety, mechanical safety, functional safety and information security. It reduces personnel risks effectively, boasts high reliability and flexible deployement.

Picking / Putaway Workstations

.png?width=160&height=100&name=image%20105%20(1).png)

Safety Doors & Safety Fence System

.png?width=160&height=100&name=image%20(58).png)

Maintenance Area

.png?width=160&height=100&name=image%20(59).png)

Robot Area

Transform Your Supply Chain today

Reach out to our team for enquiries, sales, virtual demo, live demo and other informations

FAQs

Geekplus robots combine advanced technologies like LiDAR, visual SLAM, and inertial navigation systems for precise localization, navigation, and operation. With energy-saving capabilities reducing consumption by up to 75% compared to manual warehouses, 24/7 operation efficiency, and long-lasting rechargeable batteries, Geekplus sets the benchmark for warehouse robotics.

Geekplus solutions are modular and designed for scalability. Businesses can start small and expand easily by adding robots, shelves, or workstations. Systems like the STP (Shelf-to-Person) and RS Air handle peak loads seamlessly, ensuring flexibility during rapid growth or market fluctuations.

Geekplus systems include robust safety features such as multi-sensor obstacle avoidance, compliance with electrical and mechanical safety standards, and secure operational environments. With tools like safety doors, fences, and designated maintenance areas, Geekplus ensures both operational and personnel safety.

Geekplus combines cutting-edge robotics with efficient software solutions, offering unmatched scalability, reliability, and support for a wide range of industries. With global recognition and the ability to transform supply chains, Geekplus empowers businesses to stay competitive in a fast-growing market.