Robotics Solutions which make warehouse

The complete robotics suite which gives you flexible, modular & multi-combination system that scale with your warehouse needs.

Whether you store goods in totes, shelves or pallets, our solution can handle everything in your warehouse. From picking, sorting & putting away small goods to handling, moving and storing heavy pallets, Geek+ Solutions can do it all.

.png?width=940&height=788&name=Happy%20Family%20Photo%20Collage%20Facebook%20Post%20(1).png)

Robotics Solutions which make warehouse

The complete robotics suite which gives you flexible, modular & multi-combination system that scale with your warehouse needs.

Whether you store goods in totes, shelves or pallets, our solution can handle everything in your warehouse. From picking, sorting & putting away small goods to handling, moving and storing heavy pallets, Geek+ Solutions can do it all.

.png?width=854&height=1326&name=f.658(1).png)

Transform Your Warehouse into a Next-Gen Fulfilment Center

with a One-stop Partner for Warehouse Robotics

Geekplus automates warehouse operations for retailers, logistics providers, and e-commerce fulfillment.

#1 AMR Leader for 6 consecutive years

Warehouse Operations are Complex.

Robotic Solutions, All in one place

Comprehensive automation solutions designed to transform every aspect of your warehouse operations

Geek +

SOLUTIONS

Geek+ Fulfillment Systems

Intralogistics Modules

Supporting Modules That Keep Everything Moving

These modules handle what happens beyond the core Geek+ systems managing internal transport, sorting, staging, and pallet handoffs across your warehouse. From truck to grid, dock to storage, or warehouse to production line, they ensure every process stays synchronized with your goods-to-person operations.

InstaMove

Plug & Play Internal Transport solution (Transport /+ GTP Robots /+ Forklifts) with <10 units

RoboArm

Robotic arm for precise item picking

Sorting Solutions

Parcel, SKU, or order line sorting with full flexibility

Forklift

Automate pallet putaway, restocking, and dispatch

Material Transport

Transfer between workstations, zones, or trailers

Your One-Stop Partner for Warehouse Robotics

GeekPlus provides end-to-end robotics solutions that seamlessly integrate across every industry, storage type, process, and business scenario for complete warehouse optimization.

Bigger Impacts

0

Tasks orchestrated daily

0

Tasks per second handled by RMS

0

Robots deployed globally

0

Productivity boost for customers

0

Warehouses optimized

0

Error rate in picking operation

0

Faster deployment vs competitors

0

Countries Served

Your One-stop Partner for Warehouse Robotics

Business Scenarios

Warehouse Processes

Storage Types

Powered by a Unified System

All GeekPlus robotics solutions are powered by our intelligent warehouse management platform

and a range of smart robots, providing seamless integration, real-time monitoring, and data-driven optimization across your entire operation regardless of complexity or scale.

All-in-One Software

A Software Suite which is modular, efficient, reliable, flexible and provide seamless integration with 3rd party softwares.

Core Software

WES RMS IOP

Easy Integration

WMS ERP MES

Simulation & Visualization

G-Studio

3D Real-time Data

System Portal

One-Stop Partner for Warehouse Robotics

From pieces to pallets, our solutions streamline every stage from inbound to outbound across all industries, optimising space, labor, and speed.

SOLUTION 1

Shelf to Person

3x Faster Picking

Robots deliver shelves to your station, cutting travel time and labor costs while boosting throughput.

SOLUTION 3

Pallet to Person

Easy Heavy Lifting

Seamlessly integrates storage and picking operations, deliver- ing high-density storage and high throughput capabilities.

MORE SOLUTIONS

Geek +

Robots enabling automation

Seamless Integration

Geekplus robotics solutions work seamlessly with your existing systems and technology stack

ERP Systems

Seamlessly integrates with all major Enterprise Resource Planning systems

-

SAP

-

Oracle

-

Epicor

-

Microsoft Dynamics

-

Infor

-

System Portal

-

& more

WMS Platforms

Works alongside your existing Warehouse Management System

-

Manhattan Associates

-

Blue Yonder

-

High Jump

-

Infor SCM

-

Oracle WMS

Cloud Solutions

Leverages cloud technology for real-time data and analytics

-

AWS

-

Microsoft Azure

-

Google Cloud

-

IBM Cloud

-

Oracle Cloud

-

& more

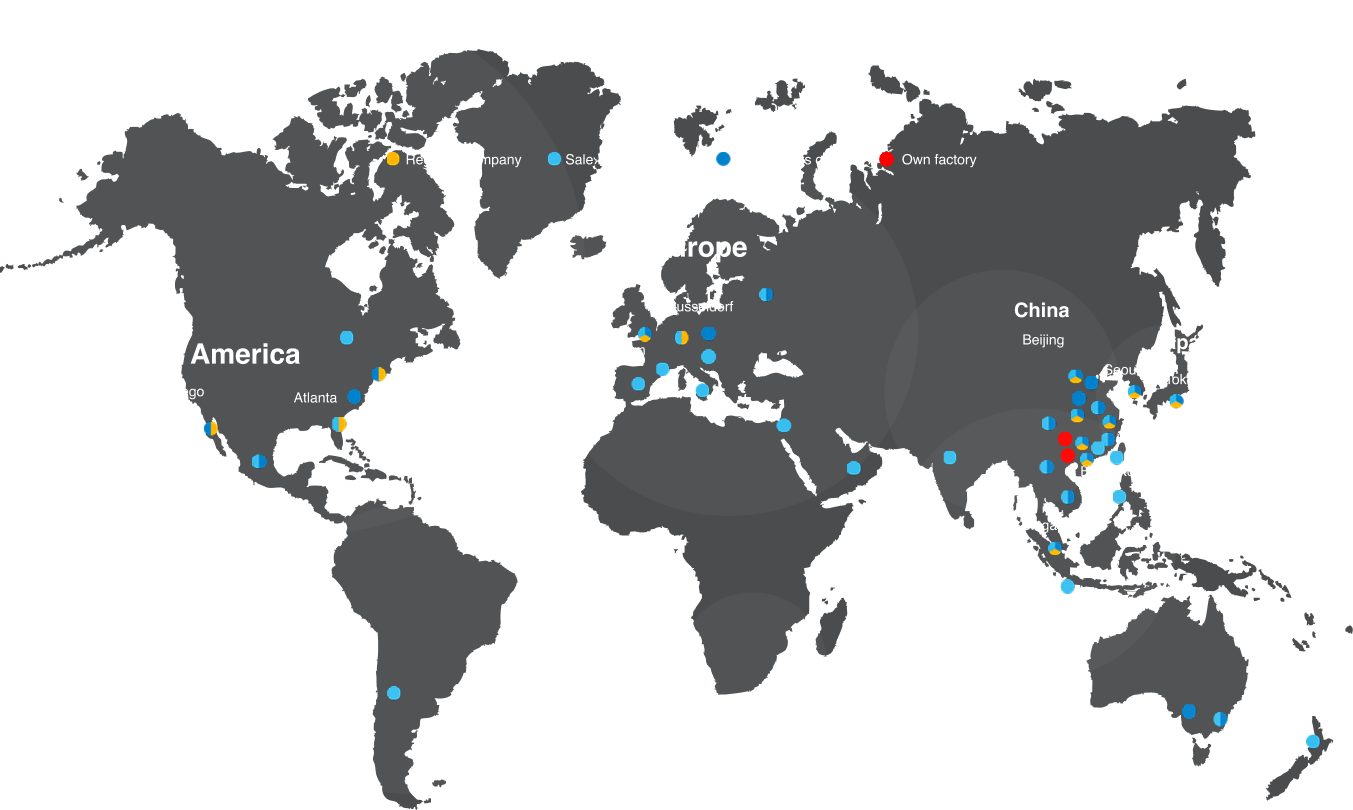

Global Network & Services

With a worldwide presence Geekplus provides consistent support and service wherever your operations are located

24/7 Global Coverage

24/7 Hotline & Support Availability

<10 min Average Response Time

40+ Service Centers & Partner Sites

12 Global Spare Parts Centers

Global Presence

North America

Europe

Asia Pacific & ANZ

Middle East & Africa

.gif?width=680&height=403&name=640%20(2).gif)

Shaping the future of Logistics

Building efficient, resilient, and future-ready operations

Get it installed today

Reach out to our team for enquiries, sales, virtual demo, live demo and other informations

Get in touchSuccess Stories

SHIP8 Warehouse Integrated Automation

The Challenge:

SHIP8 faced the need to optimize their 1.1 million sq. ft. facility.

Our Solution:

Geekplus automated SHIP8's fulfillment center with 24/7 integrated robotic arms, sorting, Shelf-to-Person, and Pallet-to-Person systems for peak efficiency.

SHIP8 INC Blue Sky Automation Oneiro Technologies

Ron Capranos, President

We’re equipped to streamline customer logistics like never before.

.png)

ASKUL Japan's Largest Shelf-to-Person System

The Challenge:

Tackled growing inventory, limited space, and scalability challenges as its products and customer base expanded.

Our Solution:

Deployed Shelf-to-Person systems with smart sorting, vertical optimization, and real-time operational insights.

Results:

- 500 lines/hour retrieval

- 318 robots worked cohesively

- faster fulfillment and scalable growth

SP Digital: Transforming Fulfillment with Scalable Automation

The Challenge:

Faced surging demand during the pandemic, with inefficient picking and limited warehouse throughput.

Our Solution:

Implemented a Shelf-to-Person solution with customized robotics, seamless integration, and a scalable design that combined smart automation with data-driven systems.

Results:

- Faster turnaround and higher throughput

- 99.99% order fulfillment accuracy

- Streamlined workflows for flexibility

- Scalable to handle demand spikes

ASDA's Scaling Grocery Efficiency

The Challenge:

Faced rapid e-commerce growth with rising forward and reverse volumes, pressure to flexibly scale order surges.

Our Solution:

Deployed Geek+ Shelf-to-Person solutions with 60 S20C robots in a 360 sqm sorting area.

Results:

- Sorted up to 2,000 parcels per hour

- Achieved 99.99% sorting accuracy

- Seamlessly adapted to rapid order volume changes

- Maintained peak performance during surges

Optimizing Nike's Supply Chain in Japan

The Challenge:

Faced rising demand, labor shortages, and productivity challenges from warehouse inefficiencies.

Our Solution:

Deployed 202 picking robots and 6,000 racks to automate retrieval and optimize storage in a 10,000㎡ CHIBA warehouse.

Results:

- Boosted picking efficiency for rising demand

- Reduced reliance on manual labor

- Enabled same-day delivery in Tokyo

- Supported e-commerce growth in Japan

Systemex Scalabled Automation for Efficient and Adaptive Operations

The Challenge:

Faced labor shortages, rising costs, and dynamic order demands needing scalable automation.

Our Solution:

Deployed Tote-to-Person AMRs with seamless integration, tailored training, and ongoing support for efficient operations.

Results:

- Faster, accurate workflows

- Reduced labor and costs

- Scalable for growth

- Adaptable to market changes

What Our Customers Say?

Hear from industry leaders who have transformed their warehouse operations with GeekPlus robotics

.png)

We are working with Geekplus to replicate the success of this project in other Dr. Max warehouses in Europe with the wide range of Geekplus solutions.

Dr. Max Romania

25000+ Monthly SKU Handling

99.9% Accuracy

350% Increased Efficiency

.png)

The unique solutions we provide together with our partner Geek+ will support our customers in the region to conquer their supply chain complexities and stay ahead of the competition.

Infios

3x More Throughput

99.9% Accuracy

300% Increased Efficiency

.png)

We will continue to deepen cooperation to drive full‑process intelligent upgrades and build a smart logistics ecosystem.

Shanghai Siemens Switchgear Co., Ltd.

3x Storage Increased

99.9% Accuracy

350% Increased Efficiency

.png)

The collaboration with Geek+ reflects our commitment to leveraging innovative technologies that bring value to our customers.

Wellcome Supermarket

2x More Storage

99.9% Accuracy

200% Increased Efficiency

Ready to Transform Your Warehouse Operations?

Schedule a consultation with one of our robotics experts to discover how GeekPlus can optimize your specific logistics challenges.

3D Experience

Understand the potential of Geek+ Warehouse Robotics via interactive 3D

ROI Calculator

Use interactive calculator to estimate your potential ROI with Geek+

Download Kits

Download brochures, case studies, and guides for your reference

News & Updates

FAQs

Geekplus caters to a wide range of industries, including eCommerce, 3PL, apparel, healthcare, groceries, auto manufacturing, and temperature-controlled storage. It helps businesses streamline operations, reduce costs, and boost efficiency with tailored automation solutions.

Yes, Geek + Plus automation can be integrated into traditional warehouses with minimal adjustments.

With advanced robotics like the P1200 and RS Air, Geekplus boosts picking efficiency by up to 200%. Features like dynamic slotting, seamless human-robot collaboration, and real-time task management ensure faster, error-free operations across inbound, outbound, and storage processes.

Geekplus combines cutting-edge robotics with intelligent software to offer industry-specific solutions. With faster deployment, high ROI, and unmatched operational insights, it’s the preferred automation partner for businesses worldwide looking to stay competitive in a rapidly evolving market.

No. Most of our customers continue running during setup. We design the project to minimize disruption and, where needed, phase the rollout by zones or shifts.