Intralogistics

Move, sort and orchestrate every workflow.

All warehouse deed more than just picking and storage. Automate internal transport, parcel sortation, and pallet movement between zones these solution.

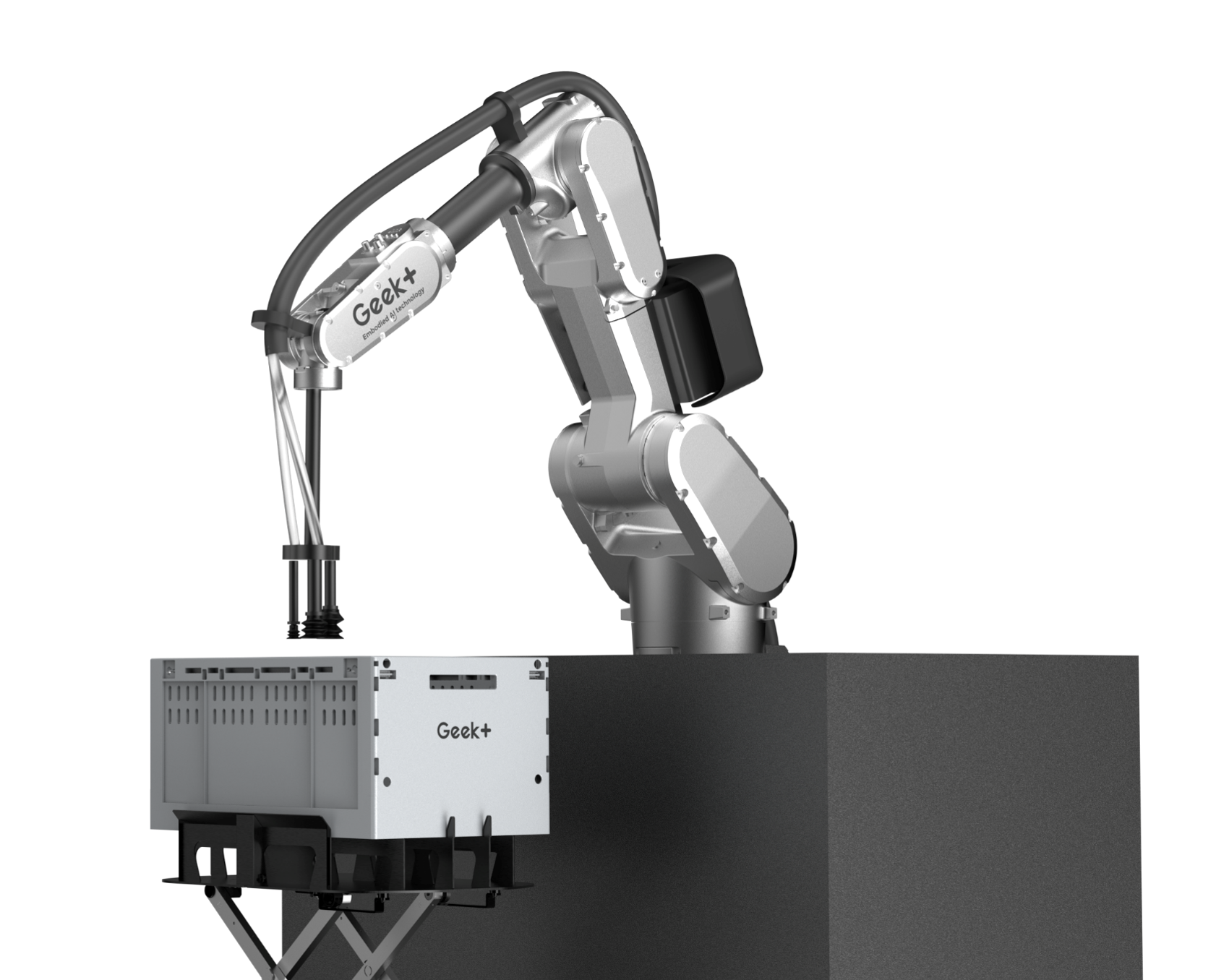

Robot Arm Picking Station

Fully Automated Picking Perfected

Geek+ RoboArm Picking Station is integrated with our Tote-To-Person Solution, enabling highly accurate and rapid 24/7 continuous piece picking operations.

.

Robot Arm Picking Station

Precise · Efficient

Description

The Geek+ Robot Arm Picking Station fully automates piece-picking within our Goods-to-Person solution. It seamlessly handles both order and batch workflows, providing 24/7 operation and the flexibility to pick virtually any SKU to provide value from day one.

Compatibility

Compatible with standard tote sized L*W: 600*400~650mm

Operational Efficiency

Up to 3~6 times higher efficiency than manual picking.

Scenario Application

Piece Picking

Robot Used

Industries Served

E-Commerce, Retail, Grocery, Pharmaceutical, Manufacturing

Scalability

Add workstations based on demand

Software Platform

RMS (robot scheduling), WES (task logic)

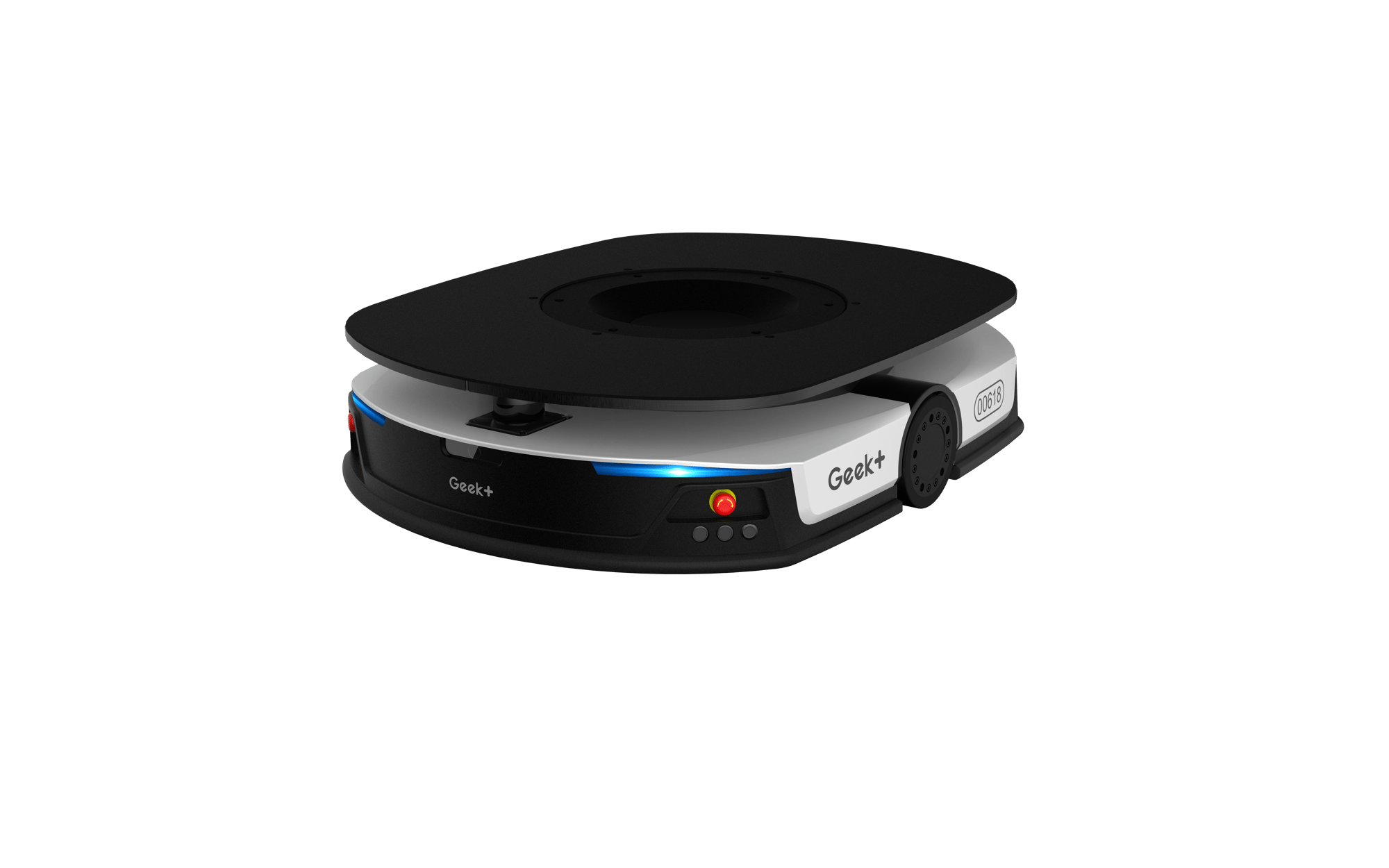

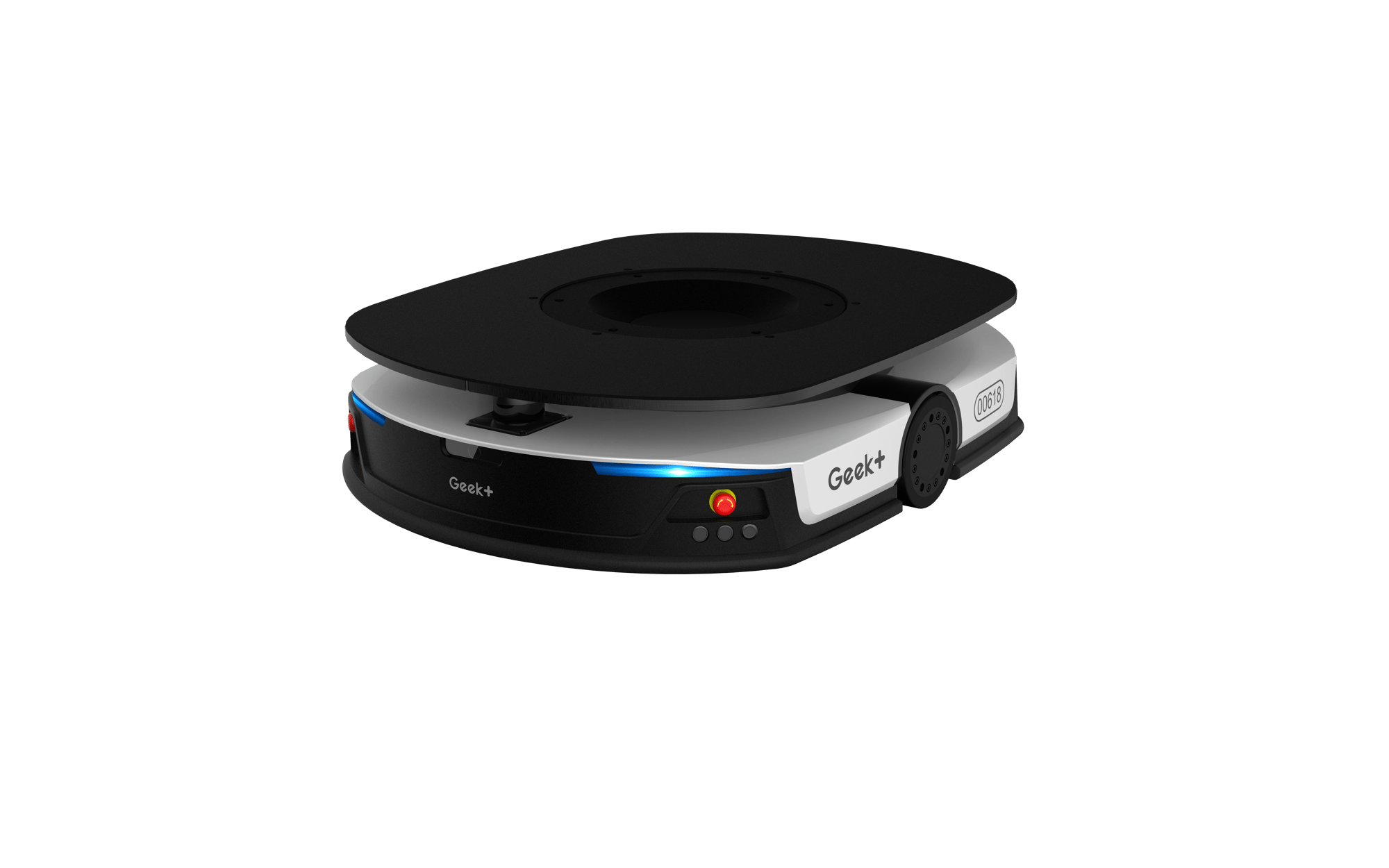

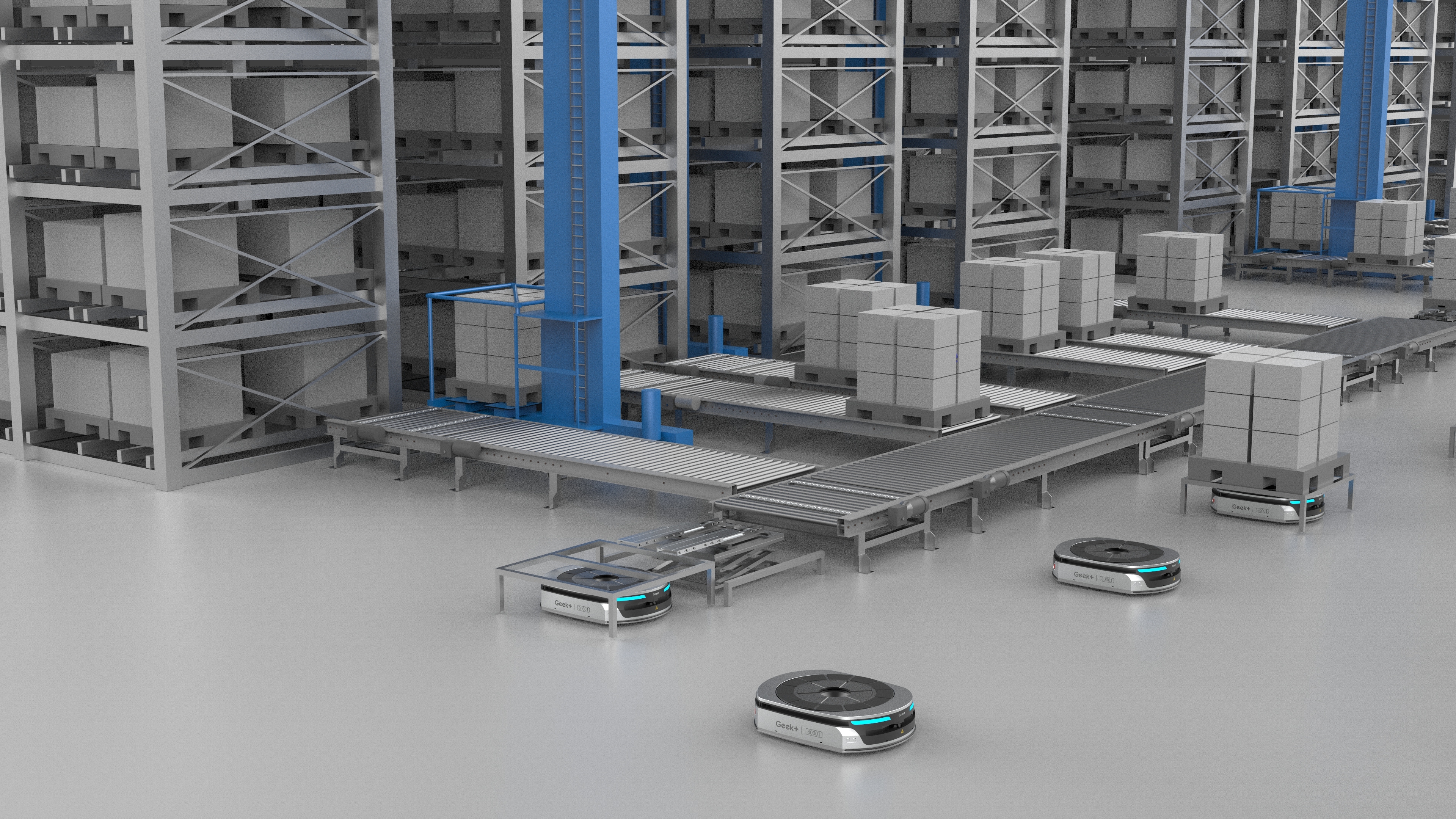

Moving

Transfer between workstations, zones, or trailers

Geek+ M-Series moving robots have a maximum carrying load of 1000kg, and are supported by laser SLAM, QR code navigation and other navigation methods to ensure smooth, accurate and safe robot operations.

Smart Moving

Precise · Safety · Efficient

Description

Geekplus material handling solutions focus on intra-factory logistics, providing plant-wide end-to-end smart logistics solutions, including raw material warehousing, feeding and removal from production lines, inter-process transfer, and finished goods warehousing.

Compatibility

Compatible with pallet rack, transfer cart, shelf, cage cart and so on.

Operational Efficiency

Up to 3x faster than manual handling, 99.99% accuracy.

Scenario Application

Inbound & Outbound; Line feeding; WIP transport; Finished goods distribution and so on

Robot Used

M-Series

Industries Served

Logistics, Automotive, Electronics, Lithium Batteries, Photovoltaics, etc.

Scalability

Add robots based demand

Software Platform

RMS (robot scheduling), WES (task logic), IOP (alerts), G-plan (simulation)

Transport

Transfer between workstations, zones, or trailers

Geek+ M-Series moving robots have a maximum carrying load of 1000kg, and are supported by laser SLAM, QR code navigation and other navigation methods to ensure smooth, accurate and safe robot operations.

Smart Moving

Precise · Safety · Efficient

Description

Geekplus material handling solutions focus on intra-factory logistics, providing plant-wide end-to-end smart logistics solutions, including raw material warehousing, feeding and removal from production lines, inter-process transfer, and finished goods warehousing.

Compatibility

Compatible with pallet rack, transfer cart, shelf, cage cart and so on.

Operational Efficiency

Up to 3x faster than manual handling, 99.99% accuracy.

Scenario Application

Inbound & Outbound; Line feeding; WIP transport; Finished goods distribution and so on

Robot Used

M-Series

Industries Served

Logistics, Automotive, Electronics, Lithium Batteries, Photovoltaics, etc.

Scalability

Add robots based demand

Software Platform

RMS (robot scheduling), WES (task logic), IOP (alerts), G-plan (simulation)

Sorting

Parcel, SKU, or order line sorting with full flexibility

Geekplus flexible sorting solution revolutionizes traditional operations like sorting and order fulfillment—delivering multi-fold higher efficiency than manual processes through automation and exceptional flexibility.

Sorting

High Accuracy, High Flexibility

Description

Powered by its intelligent sorting system managing S-series robots and smart equipment, Geekplus sorting solution upgrades traditional warehouse operations—including sorting and order fulfillment—in logistics, apparel, and FMCG warehouses/sorting centers globally.

Operational Efficiency

Higher accuracy, Up to 99.99%. Higher efficiency than manual.

Scenario Application

Order picking; Parcel sorting; Returns processing

Robot Used

S-Series

Industries Served

Postal & logistics; Footwear & apparel; E-commerce; Retail, etc

Scalability

Add robots, Racks or Work-stations based demand

Software Platform

RMS (robot scheduling), WES (task logic), IOP (alerts), G-plan (simulation)

Forklift

Automate pallet put-away, restocking, and dispatch

Geek+ F-Series moving robots have a maximum carrying load of 2000kg, and are supported by laser SLAM, QR code navigation and other navigation methods to ensure smooth, accurate and safe robot operations.

Forklift

Safe · Accurate · Swarm Intelligence

Description

Geekplus Smart Forklift automates pallet handling for inter-zone transportation scenarios. Utilizing laser SLAM navigation, it deploys without infrastructure changes while dynamically adapting to environmental shifts.

Compatibility

Compatible with multiple types of pallet:

- Different size: H-shaped pallet: 1200*1200、1200*1000、1100*1100、1200*800

- Different material: Wooden; Plastic

Operational Efficiency

Up to 3x faster than manual handling, 99.99% accuracy.

Scenario Application

Pallets storage; Line feeding; Conveyor line docking

Robot Used

F-Series

Industries Served

Lithium Battery, 3C Electronic, Atomotive

Scalability

Add robots based demand

Software Platform

RMS (robot scheduling), WES (task logic), IOP (alerts), G-plan (simulation)

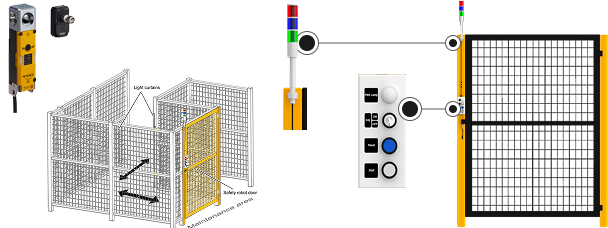

Safety & Security

PL-d level Safety Solution

Geek + has a professional safety design, safety research and development, safety implementation, and safety verification team to ensure the safety of each project. The complete system security solution has been certified by TUV-Rheinland and can provide functional safety protection up to PLd.

All-in-One Software

Algorithm and data driven

The Geekplus Software Suite is a series of modular software products to support efficient, reliable and flexible robot-based smart warehouse solutions.

The Geekplus Software Suite supports multiple languages and provides open interfaces, ensuring that customers and partners can easily use and integrate with.

Core Software

WES RMS IOP

Easy Integration

WMS ERP MES

Simulation & Visualization

G-Studio

3D Real-time Data

System Portal

Integrations & Tech Stack Compatibility

- Compatible with major WMS/ERP systems

- Seamless REST API + Webhook support

- Cloud or on-prem deployment options

- Real-time dashboards for ops visibility

- IT support model with 24/7 monitoring

What customers say?

.png)

"We boosted throughput by 250% without hiring. It feels like the shelves do the work."

Director of Fulfilment,

European Retailer

.png)

"What used to take a full shift now takes half. Geekplus gave us velocity without chaos."

Operations Manager,

US 3PL

More Success Stories

FAQs

Geekplus solutions automate critical workflows such as internal transport, parcel sorting, and pallet movement. By reducing manual labor and streamlining processes, these solutions shorten cycle times, boost picking accuracy, and allow warehouses to handle more orders with fewer disruptions.

Yes, Geekplus solutions are highly scalable. Whether you need additional robots, workstations, or storage racks, the system can be easily adapted to match increasing demand or changing warehouse setups.

Absolutely. Geekplus systems are designed for seamless integration, with compatibility for major Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) platforms. This ensures smooth operations without disrupting your current infrastructure.

Geekplus solutions are versatile and cater to a wide range of industries, including eCommerce, 3PL, grocery retail, apparel, electronics, cosmetics, and B2B distribution. They are ideal for businesses handling diverse SKUs, high inventory volumes, or complex operations.

Deployment times typically range from 1 to 3 months, depending on the size and complexity of your operational needs. The Geekplus team provides full support during installation and ensures minimal disruption to your ongoing activities.

Related articles

Where it all started? The Journey of ...

10 March, 2025

Industries moving forward with robotics ...

10 March, 2025