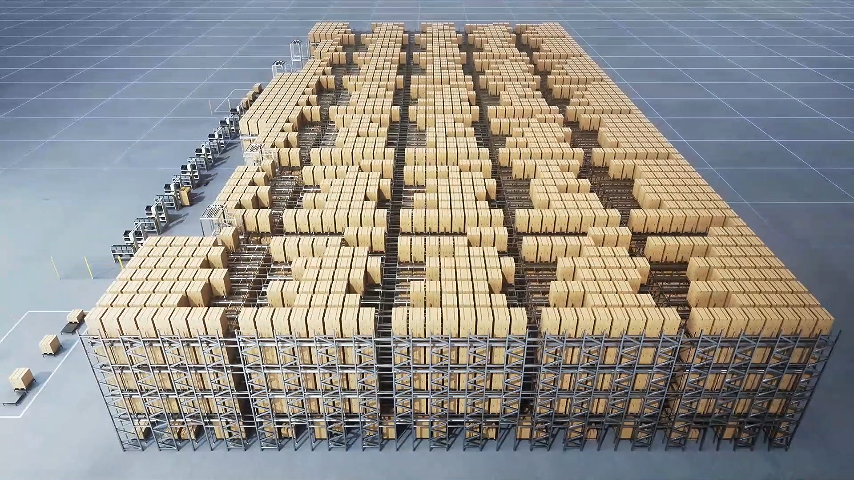

Pallet-to-Person (SkyCube)

Innovative integration of storage and picking, revolutionizing traditional warehouse automation

Store like an ASRS. Fulfill like a G-T-P. Operate as One System

Geekplus Pallet-to-Person solution is an innovative, multilevel storage-and-retrieval system (ASRS) integrated with upper-level storage and ground-level picking technology. The solution increases warehouse throughput storage capacity, operational flexibility, and can integrate with intelligent equipment (such as an unstacking machine, automatic wrapper or packer, robotic arm) to realize an unmanned smart warehouse.

Every delay in pallet handling drains time, labor, and throughput.

What if your warehouse could store full pallets and pick from them without switching systems, zones, or logic?

Designed for mixed picking- full pallets, cases, and eaches, SkyCube adapts to shifting demand and inventory structure without zone transfers or manual re-slotting.

(1)%201.png?width=491&height=379&name=%E4%B8%8A%E5%AD%98%E4%B8%8B%E6%8B%A3(%E5%B1%80%E9%83%A8)(1)%201.png)

Dense Storage & High Throughput Robotic Solution

High Density Storage | High Efficiency | Integrated Scheduling

Pallet-to-Person Configuration

High throughput, dense storage

Description

SkyCube is a Pallet-to-Person solution that seamlessly integrates dense pallet storage and shelf-level picking within one system. It automates full pallet moves, manages partial pallet returns, and enables precise piece picking—all from a unified platform.

Picking Workflow

SkyCube stores full pallets across multiple levels up to your warehouse ceiling. Using 4-way shuttles and vertical lifts, it retrieves pallets and routes them to either pick stations or buffer zones based on task logic. Operators can pick directly from pallets or from shelf zones replenished by open pallets—all in one system with no duplicate zones.

Racking Height

Max Warehouse Ceiling height

Slotting & Hit Rate

Dynamic slotting optimised by order data, SKU popularity, Optimisation during idle time

Workstation Design

.png?width=200&height=220&name=P800%E6%95%B4%E4%BD%93%E9%97%A8%E6%9E%B6%201%20(5).png)

Ergonomics

No-ladder, optimised pick height, reduced strain

Operational Throughput

Higher throughput, Up to 3x faster than manual picking

Robot Used

X-Series X1200Z

Deployment Time

Depends on the project

Industries Served

Retail, 3PL, FMCG, Pharmaceuticals, Automotive

Scalability

Add robots, Racks or Work-stations based demand

Software Platform

RMS (robot scheduling), WES (task logic), IOP (alerts), G-plan (simulation)

High Density Storage

High Efficiency

Integrated Scheduling

Integrated RMS system coordinates various devices for smoother operation and simpler deployment; enables large-scale, multi-floor, and inter-floor robot cluster scheduling.

One-stop Partner

for Warehouse Robotics

Built for Every Need in Your Industry

From cold chain and high-SKU retail to manufacturing and 3PLs, SkyCube adapts to your layout and order logic. It’s not just smart storage. It’s fulfillment-ready infrastructure capable of handling pallets, inner packs, and individual units from one footprint.

3PL & E-commerce

Serve diverse clients with dynamic inventory, fast turnarounds, and unpredictable peaks. SKU Complexity : High

Multi-client Agility + Dense Storage

Built for Multi-tenant fulfilment, cross-border logistics, D2C enablers.

Geek+ Solution

B2B Retail Distribution

Bulk replenishment, tight SLAs, and channel-specific requirements.

SKU Complexity : Medium

High-throughput + replenishment precision

Built for National retail DCs, franchise distributors, multi-format B2B hubs.

With Geek +

OmniChannel

Click-to-store, D2C, in-store fulfilment

SKU Complexity : High

High configurability + Flexible wave/batch picks

Built for Department stores, regional fulfilment hubs, omni-channel DCs.

With Geek +

Grocery Retail

From chilled to ambient, STP supports zone-based picking with speed and safety, perfect for high-velocity, time-sensitive orders.

SKU Complexity : Medium

Zone picking + freshness-first

Built for National retail DCs, franchise distributors, multi-format B2B hubs.

With Geek +

Apparel & Footwear

Perfect for high-SKU, low-unit warehouses. Manages seasonality, returns, and odd-shaped items with ease. SKU Complexity : Medium

Flexible wave/batch picks

Built for National retail DCs, franchise distributors, multi-format B2B hubs.

Geek+ Solution

Any Industry

Bulk replenishment, complex SLAs, and omni-channel logistics.

SKU Complexity : Medium

Flexible wave/batch picks

Built for National retail DCs, franchise distributors, multi-format B2B hubs.

With Geek +

Built for Every Storage Type in Your Industry

No two warehouses are alike. STP tailors itself to your unique footprint, SKU mix, and throughput targets—seamlessly handling every size, shape, and even the most irregular items

Storage Types

Storage on pallets and shelfs

.png?width=339&height=233&name=Frame%201171275885%20(2).png)

.png?width=339&height=233&name=Frame%201171275885%20(2).png)

Item Types Handled

Full-pallet; Cases; Each items

Built for Every Process in Your Industry

All warehouse processes can be managed by Geek+ System and Solution with ease.

Pallet Storage

Multi-level racking stores full and partial pallets efficiently.

Pallet Retrieval

Four-way shuttles manage deep lane storage and fast pallet handoff.

Case & Each Picking

Operators can pick cases or pieces directly from pallets at ergonomic stations.

Replenishment

Fast pallet-to-shelf transfer supports SKU decanting or restock.

Returns & Restaging

Supports dynamic buffer zones and returns handling for open pallets.

Modular Architecture, Not Fixed

Geekplus Pallet-to-Person brings entire shelves directly to your operators for lightning-fast picking, reduce walking, speed up the fulfilment, and make onboarding nearly instantaneous. Ideal for small to mid-sized warehouses with a wide range of SKUs. Choose PopPick for maximum throughput and smallest footprint.

Workstations

High efficiency | User-friendly

Geek+ workstations designed for high throughput, strong compatibility, and large storage, which delivers safe, efficient order picking with a user-friendly, ergonomic design that boosts productivity and user experience.

.png?width=521&height=220&name=Group%2083%20(4).png)

All-in-One Software

Algorithm and data driven

The Geekplus Software Suite is a series of modular software products to support efficient, reliable and flexible robot-based smart warehouse solutions.

The Geekplus Software Suite supports multiple languages and provides open interfaces, ensuring that customers and partners can easily use and integrate with.

Core Software

WES RMS IOP

Easy Integration

WMS ERP MES

Simulation & Visualization

G-Studio

3D Real-time Data

System Portal

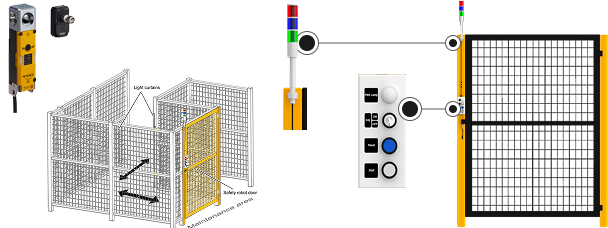

Safety & Security

PL-d level safety solution

Geek + has a professional safety design, safety research and development, safety implementation, and safety verification team to ensure the safety of each project. The complete system security solution has been certified by TUV-Rheinland and can provide functional safety protection up to PLd.

Support

Local services covering the globe

Geek+ provides reliable and comprehensive services with the best service quality, fully achieving system availability and system efficiency, and covering sales, operation and service capabilities in about 40 countries.

What customers say?

.png)

"We boosted throughput by 250% without hiring. It feels like the shelves do the work."

Director of Fulfilment,

European Retailer

.png)

"What used to take a full shift now takes half. Geekplus gave us velocity without chaos."

Operations Manager,

US 3PL

More Success Stories

FAQs

The PTP solution enhances productivity by automating pallet movement, reducing operator walking time, and streamlining workflows. It achieves faster picking, optimized storage, and increased throughput, making your operations more efficient and scalable.

Starting from the two aspects of warehouse rent cost and labor cost, optimize the operating cost of the logistics center to achieve rapid returns.

The PTP solution is highly scalable, allowing you to add more robots, workstations, or racks as business demands grow.

Yes, the PTP solution is compatible with all major Warehouse Management Systems (WMS) and ERP platforms, offering seamless integration through REST API and Webhook support for smooth operations.

Related articles

Where it all started? The Journey of ...

10 March, 2025

Industries moving forward with robotics ...

10 March, 2025