X Series

- Four-way Shuttle

Geek+ X- Series robots can support high density storage and flexible scheduling. It has ultra-thin 125mm body design, which can effectively reduce the track height, saving 14% rack cost.

Working 24x7

Enables Pallet-to-person and other solutions

X Series Model

SkyCube Pallet-to-Person solution use X1200 to achieve integrated storage and picking with high-density storage and high throughput capabilities. It increases storage capacity, throughput, and flexibility, and is cost-effective.

X1200Z

Applications

B2B and B2C situations requiring high storage density and picking efficiency require working with whole pallets, original containers, and piece picking of small, medium, and large items.

Applicable Industries

manufacturing, retail, 3PL, FMCG, pharmaceuticals, cold chain, etc.

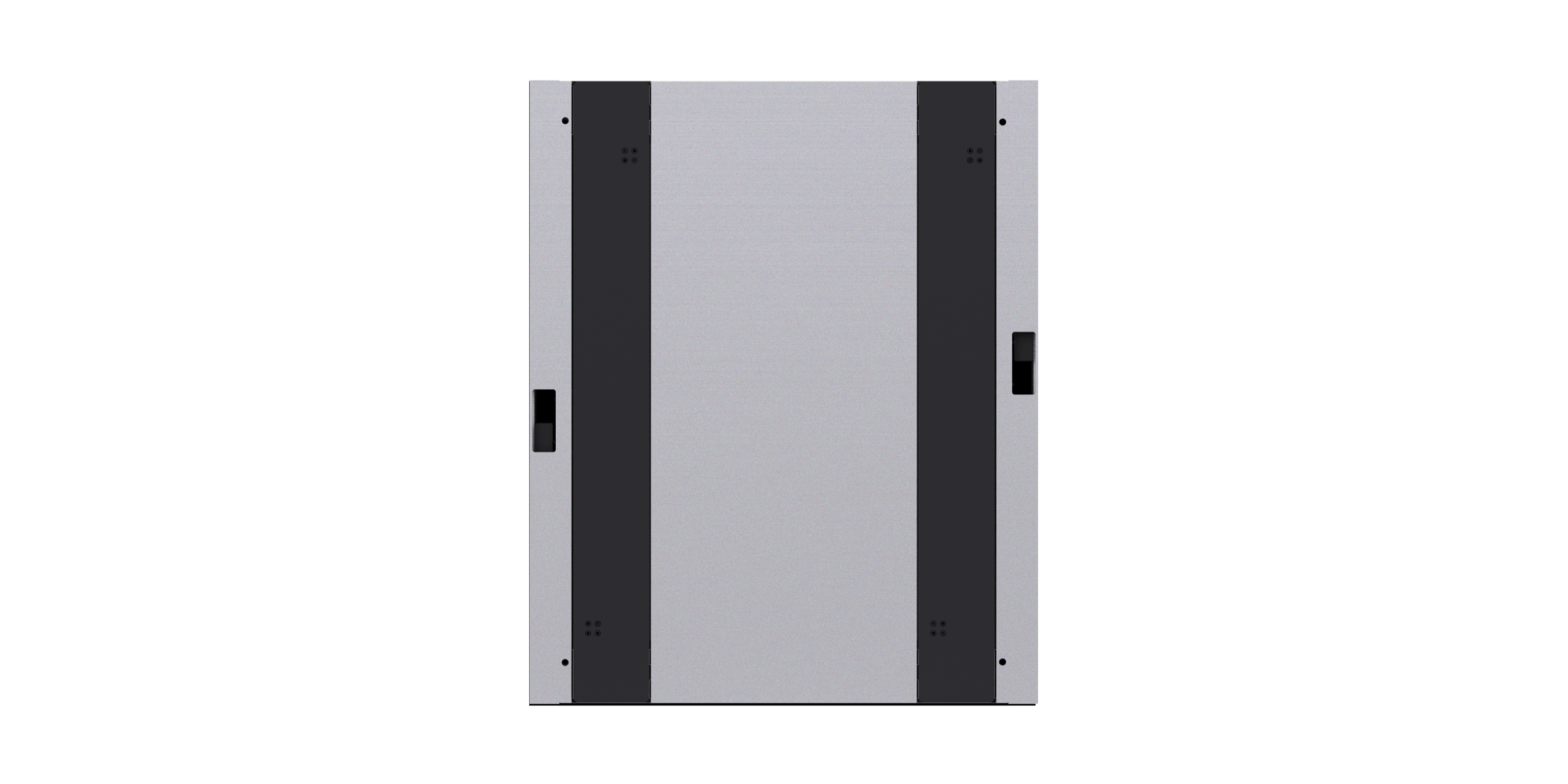

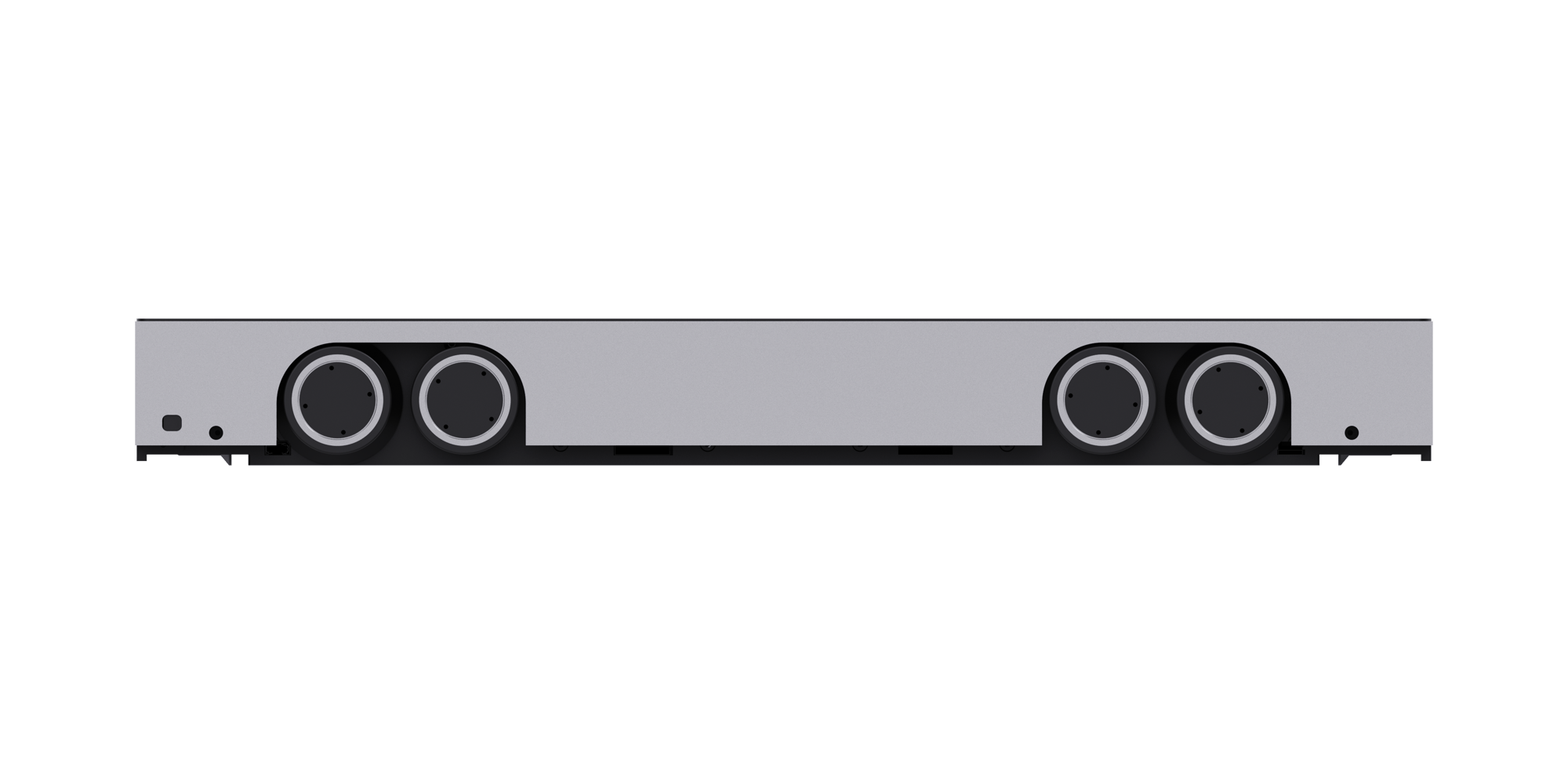

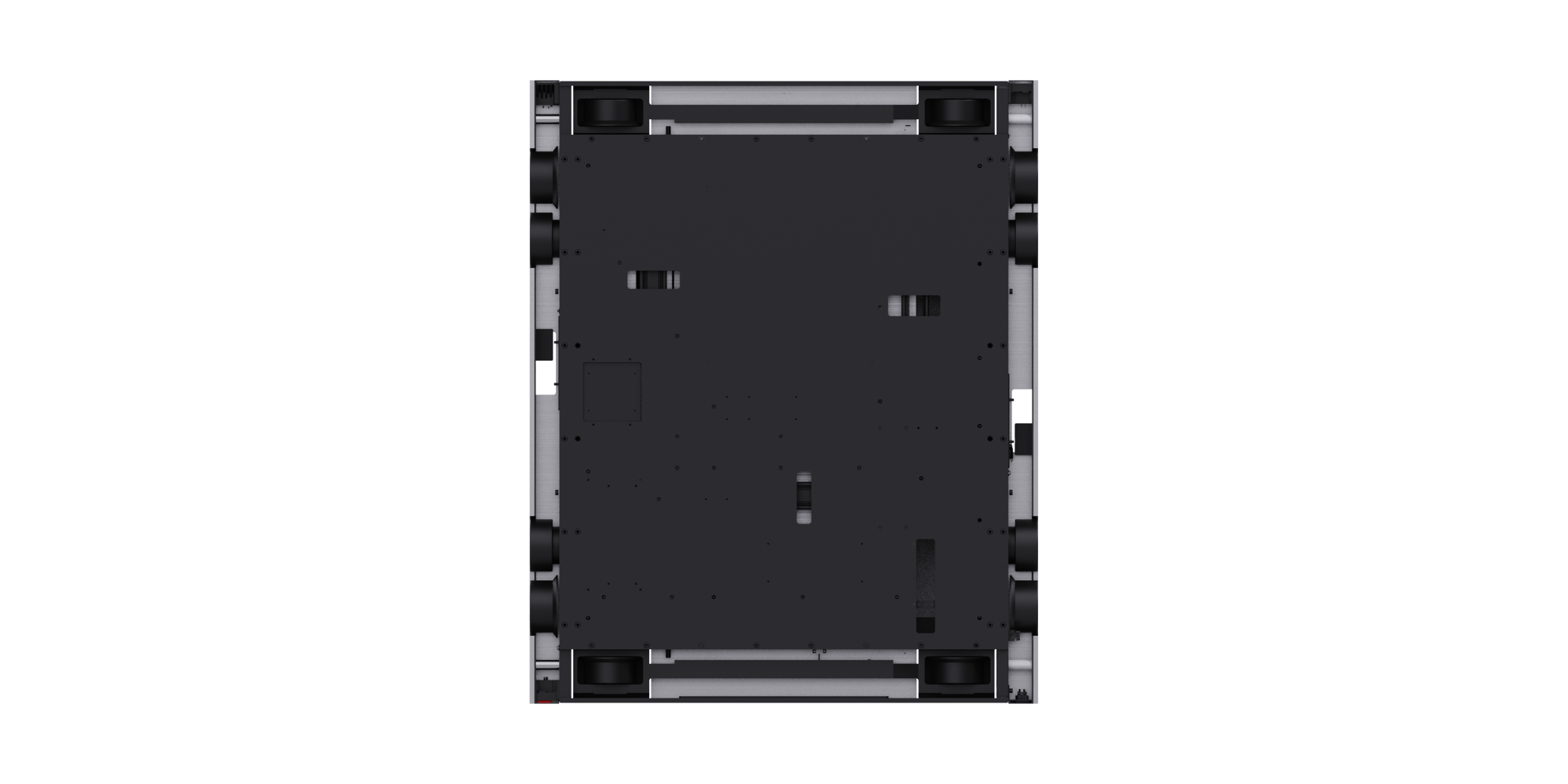

Views and Specs

Select a Model

X1200Z

Select a view

Specifications

Maximum Payload

1200 Kg

Maximum Speed with Load

1.6 m/s

Minimum Lifting Time

2.5 s

Maximum Speed without Load

1.5 m/s

Maximum Lifting Height

35 mm

Dimensions

1000mm X 972mm X 125mm

Weight

270 Kg

Powered by All-in-One Software

The Geekplus Software Suite is a series of modular software products to support efficient, reliable and flexible robot-based smart warehouse solutions.

The Geekplus Software Suite supports multiple languages and provides open interfaces, ensuring that customers and partners can easily use and integrate with.

G-Studio

G-Service

RMS

WES

IOP

System Portal

Transform Your Supply Chain today

Reach out to our team for enquiries, sales, virtual demo, live demo and other informations

Download Brochures & Solution Kits

Robosavior Guide - Peak Terminator 8

6 March, 2025

Robosavior Guide - Peak Terminator 7

6 March, 2025

Robosavior Guide - Peak Terminator 6

6 March, 2025

Related Case Studies

Case Studies

Doing More with Less: How Geekplus Robotics ...

9 September, 2025

Infios and Geekplus drive efficiency in ...

18 August, 2025

FAQs

Geekplus robotics technology features advanced innovations like modular designs, real-time monitoring, and intelligent navigation systems. These technologies allow businesses to optimize warehouse operations, increase productivity, and reduce operational costs.

Yes, Geek + Plus automation can be integrated into traditional warehouses with minimal adjustments.

Key specifications include:

- Maximum Payload Capacity: 600 kg

- Maximum Speed with Load: 2 m/s

- Minimum Lifting Time: 4 seconds

- Dimensions: 950mm x 702mm x 275mm

- Maximum Shelf Size Supported: 880mm x 880mm

These features ensure high performance and stability for diverse warehouse tasks.

Geekplus solutions are modular and scalable, allowing businesses to expand operations effortlessly by adding robots, storage units, or workflows. This flexibility ensures high efficiency during business growth phases without overhauling existing infrastructure.

Geekplus combines advanced robotics with a robust software suite for seamless integration, providing unmatched accuracy, speed, and flexibility. Its solutions are globally recognized and cater to industries like eCommerce, grocery, pharma, and 3PL, making it a trusted leader in warehouse automation.