From BOM to Buffer to Box

Automate warehouse and in-plant logistics for electronics manufacturing

Whether you're staging split kits, building by BOM, or coordinating QA loops, Geekplus helps 3C and component brands speed up fulfillment with unmatched precision and traceability.

30+

Electronics Projects Live Globally

70%

Walking Distance Reduction per Operator

60%

Fewer Picking Errors

20,000+

SKUs Handled Across Bins, Trays, Totes, and Cartons

Up to 2x

SKUs Handled Across Bins, Trays, Totes, and Cartons

1–3 month

Average Deployment Timeline

What Our Customers Are Saying

.png)

"20,000 SKUs across formats in one system. Kitting is now 4x faster."

Director of Fulfilment,

European Retailer

.png?width=2394&height=1336&name=a63627ba850b7c8c24ab0b68b5525d7060361387%20(1).png)

3x Higher Throughput

99.9% Accuracy

300% Increased Efficiency

We understand Your Challenges

From multi-client cold chain logistics to ecommerce fulfillment, we help you handle client complexity, space constraints, labor volatility, expanding SKUs, flash sales, reverse logistics and more with ease.

High SKU Complexity

Trays, bins, cartons, pallets, and ESD requirements in one flow.

BOM-based Picking and Kitting

Support pick-by-part, versioning, and A/B zone separation.

Split Inventory and Multi-client Flows

One grid for OEM, contract manufacturing, DTC, and returns.

Refurbishment and Test-stage Handling

Reslot or rework items with traceability intact.

Space and Labor Constraints

Retrofit in tight warehouses, operate 24/7 with fewer shifts.

Accuracy and Traceability

Automate QA, rebin, batch control, and zone-level routing.

Geek+ Solutions for Every Electronics Challenge

Geekplus Goods-to-Person systems automate your full fulfillment flow, from pallets to pieces, with real-time control across zones and clients.

Handle sensitive SKUs and high mix-low volume inventory with ease.

Ideal for

3C OEMs

Contract manufacturers

Chip/PCB vendors

Electrical parts distributors

3PLs handling electronics

Regional eCom hubs

Your One-stop Partner

for Warehouse Robotics

Built for Every Scenario in Electronics

Every client brings their own channels, rules, and delivery promises. We help you switch between them without switching up your operation. From retail pallets to DTC parcels, Geekplus helps 3PLs run everything through one streamlined flow.

Multi-part BOM Staging

Auto-sequence kits and components across formats.

QA Inspection Buffers

Store and route based on test results or hold status.

Split-case and Tray Flows

ESD trays, totes, and bins managed without rebinning.

Returns and Repair Logistics

Closed-loop test–repair–repack–restock workflows.

DTC and B2B Hybrid Sites

Task-based routing for wholesale and eCom flows together.

Built for Every Warehouse Process in Electronics

Reduce material handling time by up to 50% and increase throughput by 2–3×, all while ensuring ESD safety and material traceability.

Seamless integration of storage, picking, kitting, and line-feeding for electronics manufacturing.

Inbound Receiving (tray/tote/carton)

Automated Putaway with Storage Rules

Pick-to-kit Logic by BOM or Order

Sorting and Staging by Zone/Client

Buffer and QA Zone Management

Returns and Test-stage Reslotting

Built for Every Storage Type in Electronics

Every electronics warehouse deals with mixed inventory from bulk pallets to individual pieces. Geekplus systems adapt to your SKU profile, allowing flexible storage and picking of pallets, totes, and pieces within a single system.

ESD trays → PCB, chips, soldered units

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

.png?width=491&height=232&name=Frame%201171275885%20(1).png)

Totes & bins → High-density component SKUs, kits

.png?width=333&height=232&name=Group%20237747%20(3).png)

Cartons → Consumer boxes or full kits

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

Pallets → Large cases or mixed SKUs from contract lines

.png?width=333&height=232&name=Group%20237747%20(3).png)

Everything you need to automate electronics logistics—from brochures and layouts to BOM use cases and robot picks.

Why Electronics Operators Choose Geekplus?

Fast kits with ergonomic design

Reduce operator load while increasing throughput

Industry-built logic

Native support for test-stage, ESD, BOM, and zone routing

Fast kits with ergonomic design

Reduce operator load while increasing throughput

Real-time orchestration

Powered by RMS + WES for electronics rules and flows

Global trust

Projects with top 3C brands across Asia, EU, and North America

Read Success Stories

Need internal alignment for warehouse automation in electronics? Start here.

Use this industry pack to show how automation increases accuracy, traceability, and flow for high-value inventory.

Downloads

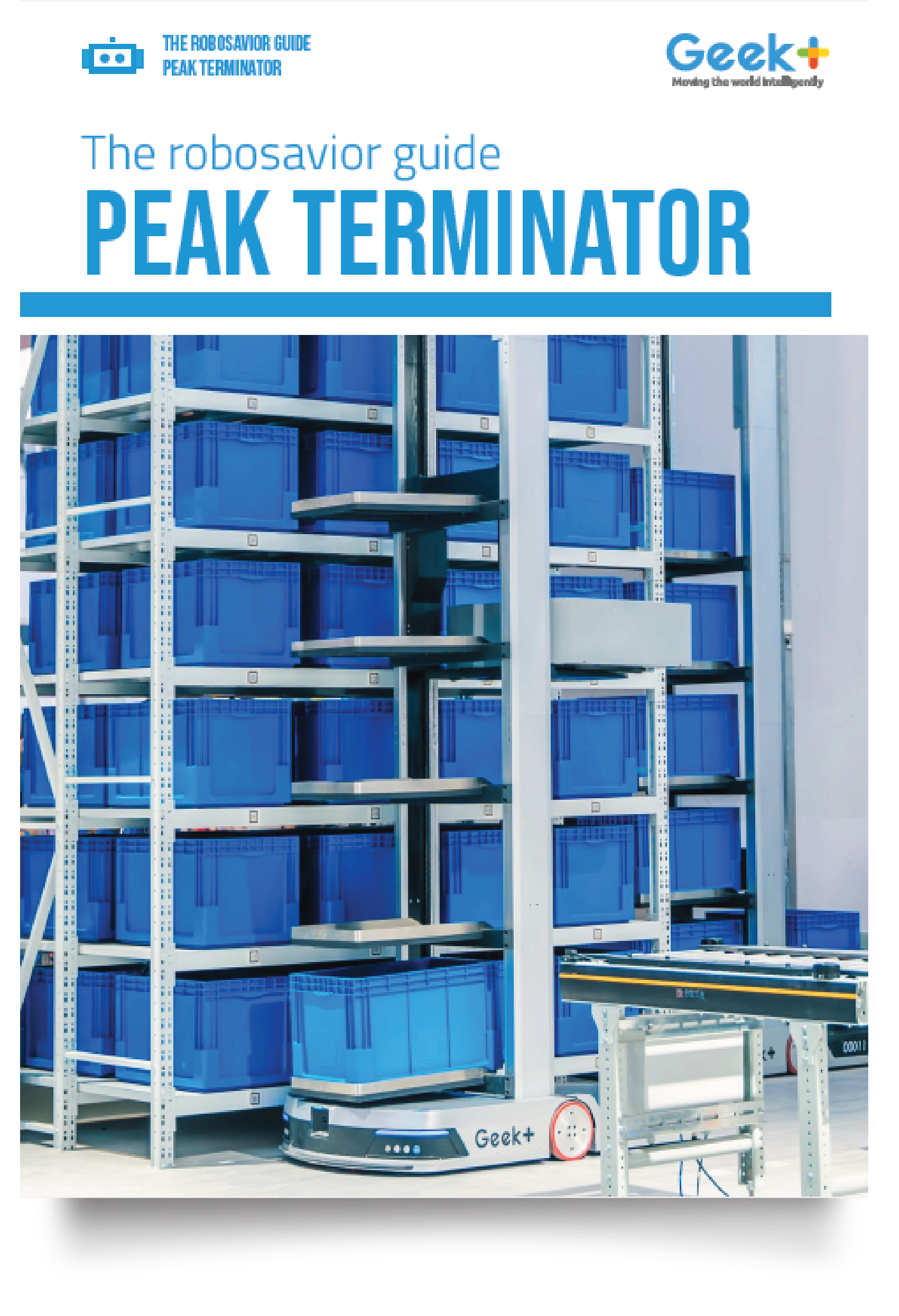

The Robosavior Guide - Peak Terminator

12 October, 2024

Download the Case Study: Hawesko

23 September, 2024

-1.png)

Vertical Height Solutions Warehouse Tour

22 July, 2024

FAQs

Geekplus solutions greatly reduce operational costs by automating labor-intensive processes like sorting, picking, and replenishment. This results in faster order fulfillment, fewer errors, and up to 300% increased efficiency, enabling a typical ROI within two years.

Related articles

Just-in-Time Restocking: Robotic Warehouses ...

12 November, 2025

Same Trust, New Playgrounds: Dr.Max’s ...

27 October, 2025

.jpg)