Tote-to-Person (RoboShuttle)

High-density vertical storage meets agile picking efficiency

From High-Frequency to Long-Tail. One System for Every SKU.

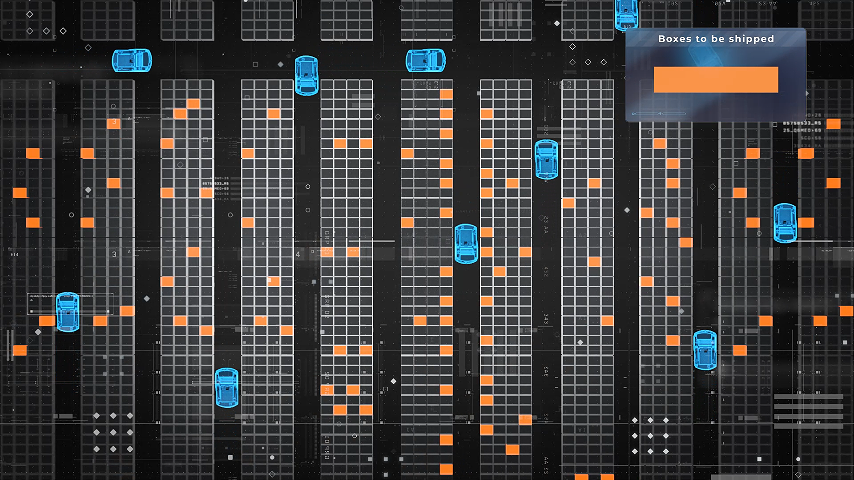

RoboShuttle V4.0 unlocks the full value of vertical storage through a decoupled, multi-agent mobile ASRS that uses task specialization to assign the right robot to the right task enabling faster picks, smarter layouts, and higher overall system efficiency.

Not All ASRS Are Created Equal

Why it outperforms other systems

RoboShuttle V4.0 combines zoning logic, shared robot efficiency, and a decoupled flow delivering speed, flexibility, and ROI that other systems can’t match.

-

Decoupled design: Vertical retrieval and horizontal transport run independently. No waiting, no bottlenecks.

-

Smart SKU handling: High-speed SKUs use RS Air; long-tail SKUs use RS mobile robots.

-

Parallel ops: RS Air, RS, and P40 work together for seamless tote delivery.

-

Scalable by zone: Expand capacity without duplicating the system.

-

Lean ROI: Higher throughput with fewer robots.

Flexible. Efficient. Accurate.

%201.png?width=369&height=356&name=RS%20(1)%201.png)

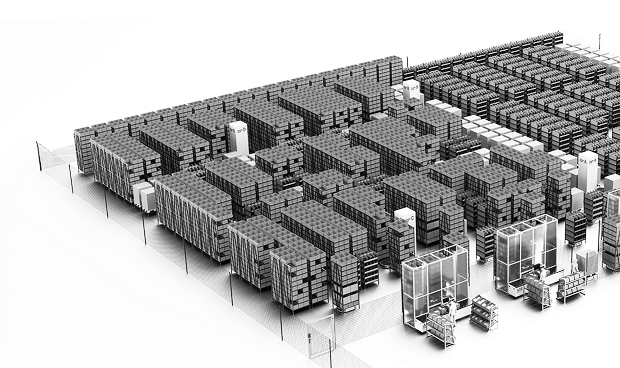

High Density. High Throughput. High Flexibility.

The RoboShuttle system offers configurations tailored to different warehouse needs. Choose the configuration that works for you. From eCommerce to 3PLs, Roboshuttle systems adapt to your layout, SKU mix, and seasonal peaks eliminating inefficiencies in labor, storage, and fulfillment.

RoboShuttle V4.0 Solution

Tote-to-Person

Mobile RS Configuration

Tote-to-Person Mobile RS + RS Air Configuration

Upgrade

Description

High-density tote storage/retrieval

Mobile RS is the core configuration of RoboShuttle V4.0, a flexible tote-to-person system using mobile robots, optimized for high-density storage up to 12m. Ideal for operations managing diverse SKUs, fluctuating volumes, and long-tail inventory.

Continuous high-throughput

An upgrade that adds rail-mounted robots for fast, stable tote retrieval up to 12m. RS Air is purpose-built for high-throughput environments, giving quick access to high-velocity SKUs and ensuring continuous tote flow to workstations.

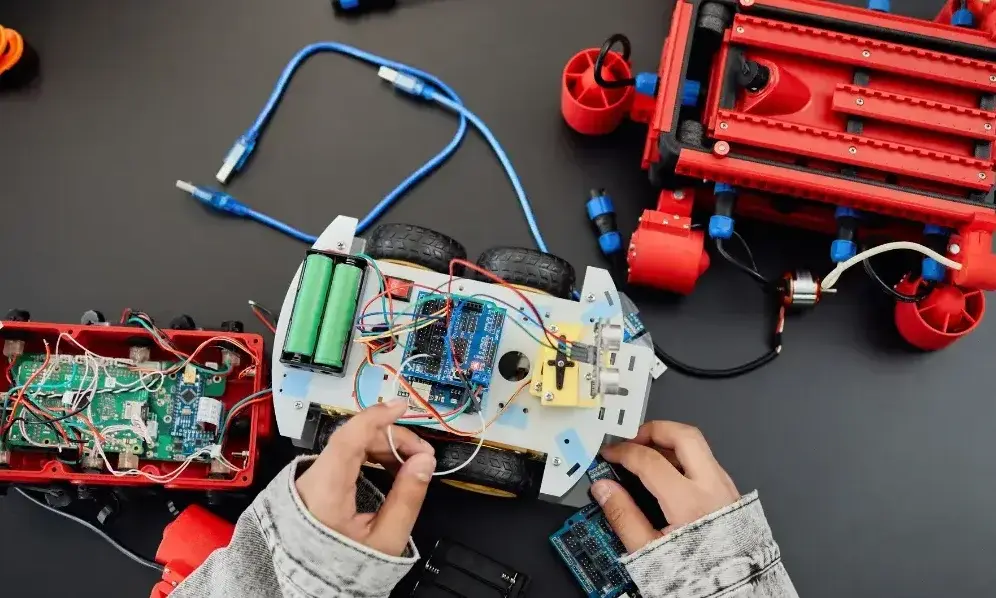

Solution Components

Robots

.png?width=198&height=260&name=P3-RS-2%20(1).png)

Mobile RS

RS AIR

Mobile robots travel across aisles to retrieve totes from racks up to 11m. Totes are staged in buffer racks, then transferred by P40 to workstations. Flexible roaming supports multi-aisle access and dynamic slotting.

Mobile RS + Rail-mounted RS Air robots retrieve fast access totes up to 12m and stage them in buffer racks. P40 handles transport to workstations.

High-density tote storage, diverse SKU management, long-tail inventory.

Mobile RS + High-velocity SKUs, peak-season demand, continuous high-throughput.

Dynamic slotting for long-tail and fluctuating demand.

Mobile RS + Prioritizes fast-moving SKUs for quick retrieval, maintaining throughput under peak load.

Shared Features

Software Platform

RMS (robot scheduling), WES (task logic), IOP (alerts), G-Studio (simulation)

Ergonomic workstations with continuous tote staging, uninterrupted flow from P40, and optimized pick height for speed and comfort.

Modular high-density racks; supports single- and double-deep layouts.

No ladders, optimized pick height, reduced operator strain.

Use Cases

Industries Served

Apparel, 3PL, Retail, eCommerce, Electronics, Cosmetics, etc.

Storage Types

Piece/ carton/ tote picking with high storage requirement

Business Scenarios

Ecommerce, B2B and B2C fulfillment, DTC, apparel returns, books, retail replenishment, and small to medium parts handling across different industries.

Warehouse Processes

Inbound, putaway, high-bay storage, replenishment, consolidation, and order picking with continuous tote delivery.

RoboShuttle V4.0 Solution

Tote-to-PersonMobile RS Configuration |

Tote-to-Person Mobile RS + RS Air Configuration |

|

|---|---|---|

Description |

High-density tote storage/retrieval

Mobile RS is the core configuration of RoboShuttle V4.0, a flexible tote-to-person system using mobile robots, optimized for high-density storage up to 12m. Ideal for operations managing diverse SKUs, fluctuating volumes, and long-tail inventory.

|

Continuous high-throughput

An upgrade that adds rail-mounted robots for fast, stable tote retrieval up to 12m. RS Air is purpose-built for high-throughput environments, giving quick access to high-velocity SKUs and ensuring continuous tote flow to workstations. |

|

Solution Components |

||

Robots |

.png?width=198&height=260&name=P3-RS-2%20(1).png)

Mobile RS |

RS AIR |

|

Picking Workflow

|

Mobile robots travel across aisles to retrieve totes from racks up to 11m. Totes are staged in buffer racks, then transferred by P40 to workstations. Flexible roaming supports multi-aisle access and dynamic slotting. |

Mobile RS + Rail-mounted RS Air robots retrieve fast access totes up to 12m and stage them in buffer racks. P40 handles transport to workstations. |

|

SKU Velocity

|

High-density tote storage, diverse SKU management, long-tail inventory. |

Mobile RS + High-velocity SKUs, peak-season demand, continuous high-throughput. |

|

Slotting & Hit Rate

|

Dynamic slotting for long-tail and fluctuating demand. |

Mobile RS + Prioritizes fast-moving SKUs for quick retrieval, maintaining throughput under peak load. |

|

Shared Features |

||

Shelf/Rack Height |

Up to 5m / 8m / 11m with double-deep rack access |

|

Deployment Time |

~1–3 months (depending on site readiness, tote zoning, and integration scope) |

|

Software Platform |

RMS (robot scheduling), WES (task logic), IOP (alerts), G-Studio (simulation) |

|

Workstation |

Ergonomic workstations with continuous tote staging, uninterrupted flow from P40, and optimized pick height for speed and comfort. |

|

Storage Density |

Modular high-density racks; supports single- and double-deep layouts. |

|

Ergonomics |

No ladders, optimized pick height, reduced operator strain. |

|

|

Use Cases |

||

Industries Served |

Apparel, 3PL, Retail, eCommerce, Electronics, Cosmetics, etc. |

|

Storage Types |

Piece/ carton/ tote picking with high storage requirement |

|

Business Scenarios |

Ecommerce, B2B and B2C fulfillment, DTC, apparel returns, books, retail replenishment, and small to medium parts handling across different industries. |

|

Warehouse Processes |

Inbound, putaway, high-bay storage, replenishment, consolidation, and order picking with continuous tote delivery. |

|

High Efficiency

Automated tote retrieval and P40 delivery minimize idle time, shorten travel paths, and boost picking speed. Operators handle more orders with less effort.

High Storage

Maximize vertical space up to 12m with dense tote spacing. Achieve higher capacity in the same footprint for better space utilization.

High Flexibility

Supports a wide SKU mix from small pieces to full cartons. Adapts to B2B and B2C workflows, returns handling, and peak-season demand.

High Throughput

Parallel robots and continuous tote staging enable fast, uninterrupted picking. Scales easily to meet surges without bottlenecks.

High Accuracy

System-directed picking reduces errors and improves order accuracy to 99.99%.

High Scalability

Add racks, aisles, or robots without disrupting operations. Expand capacity horizontally or vertically as business grows.

High ROI

Lean system design delivers faster payback through labor savings, higher storage density, and throughput gains.

High Reliability

Stable operations with intelligent scheduling and fault-tolerant design with no single point of failure.

One-stop Partner

for Warehouse Robotics

Built for Every Need in Your Industry

One platform. Every vertical. Infinite flexibility.

From ecommerce to retail, 3PL to manufacturing, RoboShuttle adapts to your warehouse needs. It handles high-density storage, mixed SKUs, and peak-season surges with RS and RS Air configurations — giving every industry the speed and flexibility to stay ahead.

3PL & E-commerce

"Clients demand faster SLAs, but SKU variety and order peaks are increasingly unpredictable. SKU Complexity : High

Multi-client Agility + Dense Storage

Built for Multi-tenant fulfilment, cross-border logistics, D2C enablers.

With Geek+

OmniChannel

Retail and online orders now ship from one DC—straining workflows and inventory zones. SKU Complexity : High

High configurability + Flexible wave/batch picks

Built for Department stores, regional fulfilment hubs, omni-channel DCs.

With Geek +

Apparel & Footwear

Managing high SKU counts, returns, and seasonality is tough in traditional bin systems. SKU Complexity : Medium–High

Fast returns processing + Flat-pack handling

Ideal for store-ready fulfillment, mixed SKU orders, and flat-packed apparel.

With Geek +

Grocery Retail

From chilled to ambient, STP supports zone-based picking with speed and safety, perfect for high-velocity, time-sensitive orders.

SKU Complexity : Medium

Zone picking + freshness-first

Built for National retail DCs, franchise distributors, multi-format B2B hubs.

With Geek +

Apparel & Footwear

Perfect for high-SKU, low-unit warehouses. Manages seasonality, returns, and odd-shaped items with ease. SKU Complexity : Medium

Flexible wave/batch picks

Built for National retail DCs, franchise distributors, multi-format B2B hubs.

Geek+ Solution

Any Industry

Bulk replenishment, complex SLAs, and omni-channel logistics.

SKU Complexity : Medium

Flexible wave/batch picks

Built for National retail DCs, franchise distributors, multi-format B2B hubs.

With Geek +

Built for Every Storage Type in Your Industry

No two warehouses are alike. STP tailors itself to your unique footprint, SKU mix, and throughput targets—seamlessly handling every size, shape, and even the most irregular items

Storage Types

.png?width=376&height=232&name=Frame%201171275885%20(1).png)

Item Sizes

Multiple sizes can be handled with this Solution

.png?width=170&height=212&name=Group%20237747%20(1).png)

Item Types Handled

Shelves can be configured to accommodate items of any shape and size

Built for Every Process in Your Industry

All warehouse processes can be managed by Geek+ System and Solution with ease.

Vertical Storage

Utilizes up to 12+ meters of height with smart bin placement and retrieval.

Picking

RS robots fetch totes from upper levels, P40 robots deliver them to ergonomic workstations.

Replenishment

Automated tote storage ensures continuous restocking without blocking operations.

Inventory Management

Accurate tote-level tracking improves visibility and SKU accuracy.

Modular Architecture

Geekplus Tote-to-Person adapts to your warehouse- scaling robots, racks, and workstations as your business grows. From tote retrieval to buffer delivery, the system is fully modular and designed to support high-density storage with flexible integration.

RS Series

Vertical Robots

Geek+ RS and RS Air robots retrieve totes from high-density racking and place them into buffer zones for picking. RS is optimized for deep, mobile access, while RS Air for high-frequency retrieval- both feeding P40 for delivery. Systems are modular, allowing robot count and rack zones to scale independently.

RS DX

RS DX

RS Air

Workstations

Built for ergonomic, high-throughput tote picking

TTP workstations are designed for continuous picking, enabling wave, batch, or sequenced orders. Integrated lights, height adjustment, and operator prompts help reduce fatigue and improve accuracy at scale.

.png?width=625&height=220&name=Group%2083%20(2).png)

All-in-One Software

Modular tools for orchestration, visibility, and control

The Geekplus Software Suite is a series of modular software products to support efficient, reliable and flexible robot-based smart warehouse solutions.

The Geekplus Software Suite supports multiple languages and provides open interfaces, ensuring that customers and partners can easily use and integrate with.

System design & simulation

G-Studio

Robot scheduling & movement

RMS

Task logic & tote routing

WES

Real-time alerts & monitoring

IOP

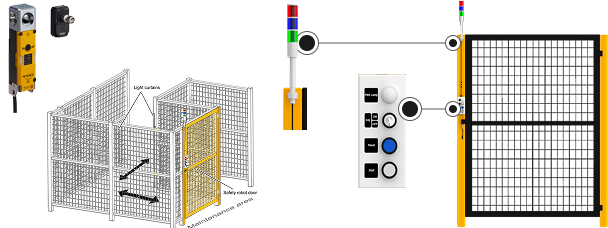

Safety & Security

Designed for safe human-robot collaboration

Tote-to-Person systems use fixed racks and guided tote delivery with physical barriers, zone fencing, and light curtains where required. Workstations are designed for operator safety during continuous high-speed picking, minimizing exposure to robot paths.

Support

Local services covering the globe

Geek+ provides reliable and comprehensive services with the best service quality, fully achieving system availability and system efficiency, and covering sales, operation and service capabilities in about 40 countries.

Shelf-to-person Workflow

Geek+ Shelf-to-Person is built for scale, speed, and smart orchestration.

Orders enter the WMS/WES.

Geekplus RMS assigns mobile robots to retrieve required shelves.

Shelves are brought directly to a picking station.

The operator picks and confirms.

Robot returns the shelf or sends it for replenishment.

Integrations & Tech Stack Compatibility

- Compatible with major WMS/ERP systems

- Seamless REST API + Webhook support

- Cloud or on-prem deployment options

- Real-time dashboards for ops visibility

- IT support model with 24/7 monitoring

What customers say?

.png)

"We boosted throughput by 250% without hiring. It feels like the shelves do the work."

Director of Fulfilment,

European Retailer

.png)

"What used to take a full shift now takes half. Geekplus gave us velocity without chaos."

Operations Manager,

US 3PL

More Success Stories

FAQs

The TTP solution streamlines operations by bringing totes directly to operators, significantly reducing walking time and manual handling. This automation boosts picking accuracy, increases processing speed, and enables warehouses to manage higher order volumes efficiently.

With the TTP solution, businesses can achieve labor cost reductions of up to 50% and improve order fulfillment accuracy. By optimizing workflows and enhancing storage utilization, the solution drives measurable cost savings and better financial returns, particularly during peak seasons.

Yes, the TTP solution offers high scalability. You can add more totes, robots, or workstations as your inventory size or order volumes grow, ensuring seamless adaptation to your expanding operations and business goals.

The TTP solution is designed for easy integration with major Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) platforms. Advanced API compatibility ensures smooth implementation without disrupting your current workflows.

The TTP solution includes predictive maintenance features, real-time system monitoring, and instant error alerts to address potential issues proactively. Combined with Geekplus’s 24/7 technical support and preventive maintenance programs, these tools ensure continuous, reliable operations.

Related articles

Where it all started? The Journey of ...

10 March, 2025

Industries moving forward with robotics ...

10 March, 2025