New Energy Manufacturing

Smart Manufacturing. Smarter Fulfillment.

Streamlined automation for spare parts, assemblies, and finished goods — from inbound to outbound.

Geekplus enables precise handling, faster throughput, and full visibility across your production and warehouse floors.

Boost efficiency and uptime with warehouse automation built for modern manufacturing.

50M+

Tasks Orchestrated Daily

1.5x

Faster Deployment Compared to Competitor

40,000+

Robots Deployed Globally

10,000+

Tasks per Second Handled by RMS

We understand Your Challenges

Manufacturers face mounting pressure to boost efficiency, reduce downtime, and ensure flawless material flow across production lines. Manual handling can’t keep up with the speed and precision modern operations demand.

Peak Load Surges

Black Friday, 11.11, Ramadan

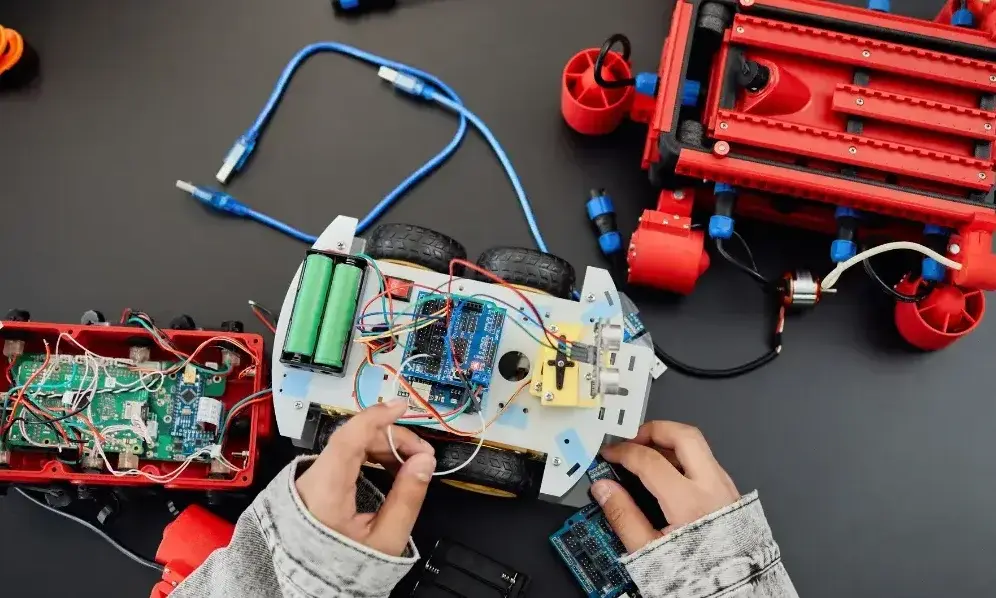

Geekplus robots collaborate with humans in the warehouses.

Multi-client & Multi-category Picking

Geekplus robots collaborate with humans in the warehouses, improving efficiency.

Parcel Consolidation and Last-mile Prep

Geekplus robots collaborate with humans in the warehouses, improving efficiency with combined precision and dexterity.

High-volume Reverse Logistics

Enable efficient coordination, accurate inventory management, and proactive decision-making with software integration.

Smart Solutions for Every Manufacturing Challenge

All powered by our Warehouse Execution System (WES) and Robot Management System (RMS)—to give you real-time visibility and orchestration across zones and clients.

You need to streamline your production flow. Let us make that easy for you.

Ideal for

EV & battery plants

Electronics assembly

Automotive parts

Industrial manufacturing

& more...

One-stop Partner

for Warehouse Robotics

Scenarios We Simplify for Manufacturers

Complex production flows. Clean execution. From raw material handling to line feeding and finished goods storage, we automate what slows you down—so you can scale faster.

B2B & B2C in One Facility

Support enterprise and consumer clients side-by-side.

Assign robots, zones, and rules per client or order type—while maintaining full visibility.

Higher margin per m², fewer constraints.

Return Processing

Speed up returns while minimising errors.

Geekplus helps you reintegrate inventory quickly, with automated quality checks and optimised storage allocation.

Faster resale, lower labor effort.

Cross Docking

Move goods between docks with zero time wasted.

Robots transfer incoming stock directly to outbound staging zones, no long-term storage required.

Maximise flow-through, minimise handling.

Omni Channel

Serve retail, B2B, and DTC, simultaneously.

Our systems manage complex order profiles and route tasks based on channel priority.

Unified operation, seamless fulfillment.

Sortation

Automate SKU, brand, or destination-level sorting with minimal effort.

Geekplus robots and software dynamically group parcels for efficient packing and shipping.

Lower error rate, faster outbound.

Warehouse Processes You Can Automate

Reduce material handling costs by up to 40–50%, and boost production flow efficiency by 2–4×—without changing your facility layout.

Seamless integration of all automation processes for the manufacturing industry.

Inbound/Put Away

- Client-specific receiving rules

- Smart slotting by volume, velocity, and value

.png?width=704&height=320&name=ec1269081bd0fddf975dfecbe8d7e5230e46b3ca%20(1).png)

Storage

- Robots optimise storage by autonomously tracking and placing items for improved inventory organisation and easy retrieval.

.png?width=704&height=384&name=cae7b1f0888c7d9a9db23842fad0e85216dbdb4d%20(1).png)

Outbound/Picking

- Goods-to-Person picking across shelves, totes, and pallets

- Parallel picking by brand, channel, or SLA

.png?width=704&height=384&name=635879e29ca80e122dc988c8d4e383ad0102190e%20(1).png)

Collaborative Workforce

- Dynamic reintegration, even for mixed SKUs

- Speedy quality control via robotic sortation

.png?width=704&height=384&name=dce203eb6bd4a100a91f3755082150933fcfc227%20(1).png)

Real-Time Visibility and Control

- Real-time dashboards

- SLA tracking for each individual client

.png?width=704&height=384&name=dceb852d2c8e743a62d7efaabcc52dfe67ba776b%20(1).png)

Quality Control

- Geekplus robots contribute to improved traceability and documentation of quality control processes

.png?width=704&height=384&name=6fa6a5944363ecbce150b78c97eb2727ac932bbf%20(1).png)

Storage types handled by Solutions

No two warehouses are alike. Shelt-to-Person tailors itself to your unique footprint, SKU mix, and throughput targets—seamlessly handling every size, shape, and even the most irregular items.

Storage Types

Handled with Shelf-to-Person Solution

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

Item Sizes

Multiple sizes can be handled with this Solution

.png?width=333&height=232&name=Group%20237747%20(3).png)

Item Types Handled

Shelves can be configured to accommodate items of any shape and size

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

You need to streamline your production flow. Let us make that easy for you.

Take the first step toward smarter, faster manufacturing. Download the exclusive Manufacturing Automation Kit and see how Geekplus can transform material handling and production efficiency.

Why Manufacturers Choose Geekplus?

Modular by design

Launch fast, expand when ready

Works with any WMS

No full rip-and-replace needed

Fast payback

Typical ROI in < 2 years

Global support

40+ countries, multi-lingual ops teams

Client-level visibility

Show your customers real-time data they’ll love

What Our Customers Are Saying

.png)

"We boosted throughput by 250% without hiring. It feels like the shelves do the work."

Director of Fulfilment,

European Retailer

.png?width=2394&height=1336&name=a63627ba850b7c8c24ab0b68b5525d7060361387%20(1).png)

3x more

throughput

99.9%

Accuracy

300%

increased efficiency

Read Manufacturing Success Stories

Let's turn your warehouse into a growth engine 🎯

Reach out to our team for enquiries, sales, virtual demo, live demo and other informations

Downloads

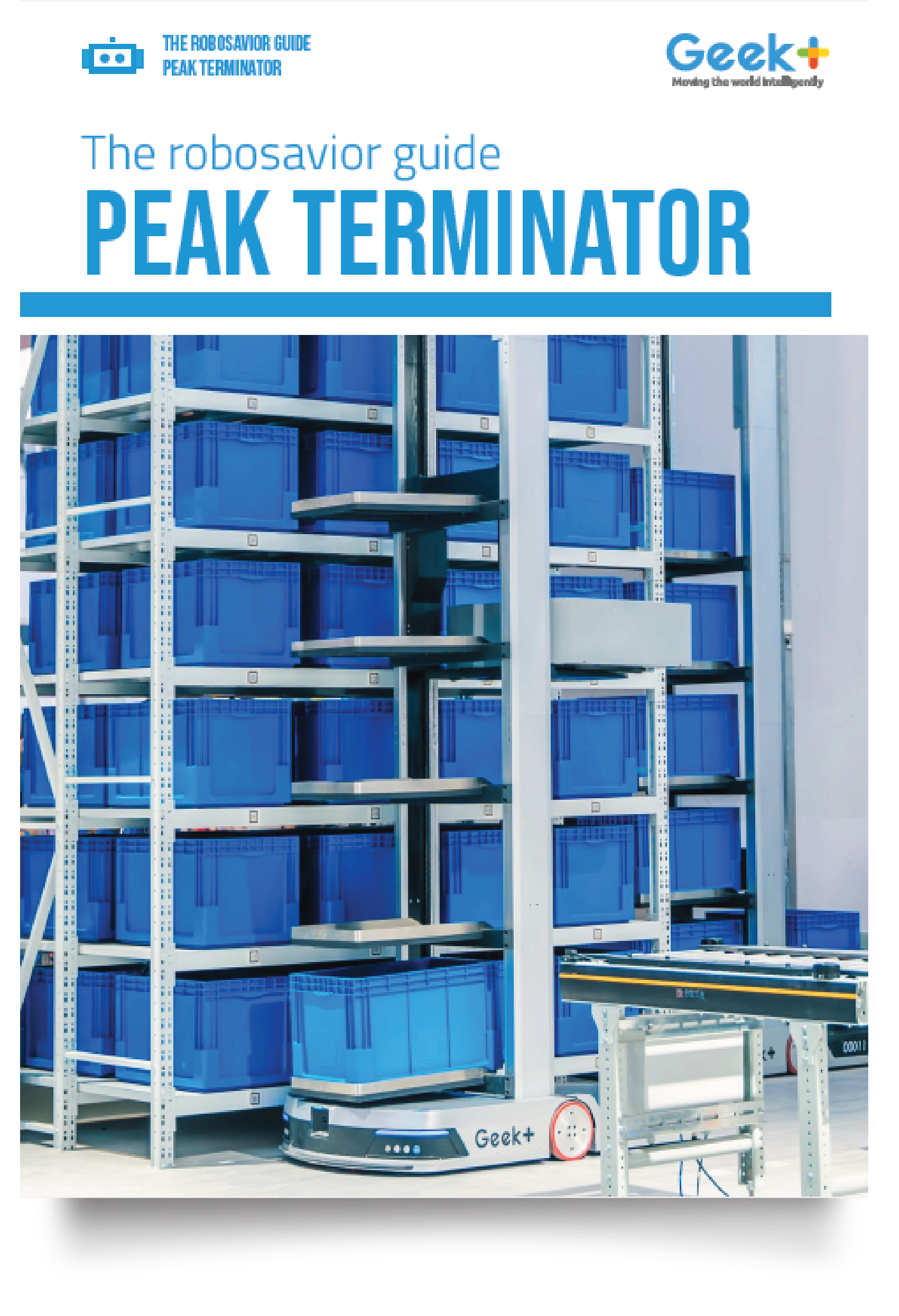

The Robosavior Guide - Peak Terminator

12 October, 2024

Download the Case Study: Hawesko

23 September, 2024

-1.png)

Vertical Height Solutions Warehouse Tour

22 July, 2024

FAQs

Geek+ provides intelligent automation solutions tailored for the new energy sector, including robotic systems for battery production, material handling, and warehouse management. Our solutions enhance efficiency, accuracy, and scalability in manufacturing and logistics processes.

Geek+ robots streamline material transportation, optimize inventory management, and ensure precise handling of delicate components. This reduces production downtime, minimizes errors, and accelerates the manufacturing cycle for batteries and other new energy products.

Yes, Geek+ solutions are highly customizable and designed to meet the unique needs of the new energy sector, such as handling hazardous materials, managing temperature-sensitive components, and ensuring compliance with industry standards.

By implementing Geek+ automation, manufacturers can achieve higher productivity, lower operational costs, improved safety, and better quality control. Our systems also support sustainable practices by optimizing resource utilization and reducing waste.

Absolutely. Geek+ solutions are designed for seamless integration with existing manufacturing and warehouse management systems (WMS), enterprise resource planning (ERP) platforms, and other operational technologies to ensure a smooth transition and enhanced efficiency.

Related articles

Where it all started? The Journey of ...

10 March, 2025

Industries moving forward with robotics ...

10 March, 2025